GAS ENGINEERS offer a complete range of magnets of all varieties to suit various applications. The magnets can be supplied in a variety of shapes and sizes including block, ring, arc segment, disk, cylinder, etc. Our magnets are known for their quality, precision and high strength.These magnets can be offered as Barium Ferrite or Strontium Ferrite grade.

They are excellent resistant to demagnetization and are the lowest cost magnets available in the market. These magnets are hard and brittle and used extensively in consumer products such as loudspeakers, headphones, micro motors, various holding magnets, health products. Isotropic and anisotropic forms are available.

These magnets are alloys of the rare earth element neodymium composed with iron and boron formulized as NdFeB. With the highest ever energy product and magnetic strength to the order of 12,000 Gauss, they are the best alternative to weight size and performance sensitive applications.

Rubber magnets are composite materials of rubber (e.g. vinyl) and magnetic ferrite powder. With the characteristics of rubber the magnets can be twisted, coiled and easily fabrication. They are widely used in various toys, boards, stationary, refrigerators, magnetic sealing, etc.

Permanent Drum type Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from Minerals, Chemicals, Food, Flour, Plastics, Grains, Sand, Cement, Fertilizers, Abrasives, Glass, Slag, Ores, Rock, Refractory and many other products.

Permanent Drum type Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from Minerals, Chemicals, Food, Flour, Plastics, Grains, Sand, Cement, Fertilizers, Abrasives, Glass, Slag, Ores, Rock, Refractory and many other products.

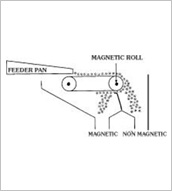

The permanent Magnetic Drum consists of stationery permanent Magnetic assembly having uniform and everlasting Magnetic field across the entire width of the drum, which is effective over approximately half the drum circumferences as shown in fig. Drum shell made of non-magnetic stainless steel revolves around the magnetic field. As material fell evenly from the chute falls over the drum, powerful magnetic, field attract & holds ferrous particles on revolving shell. As the revolving shell carries the iron particles through the stationery magnetic field, the non-magnetic material falls freely from the shell while ferrous particles are firmly held until carried beyond divider and out of magnetic field.

The strength of the permanent magnetic drum is guaranteed to be greater than corresponding electromagnetic Drum. The permanent magnets used are everlasting magnets and its strength does not diminish during normal use and can be used through out the life.

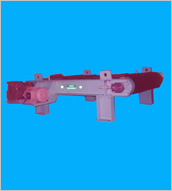

We are market leader in fabrication of indigenous high intensity, high gradient dry permanent magnetic roll separators in the Indian market. These machines are manufactured based on the advanced permanent roll technology, which has been used successfully in hundreds of industrial minerals applications around the world. We use high-energy rare earth neodymium permanent magnets assembled in a proprietary configuration to generate forces of magnetic attraction, which can be used for processing any material from ferromagnetic to weakly paramagnetic.

A short special fabric conveyor belt covers the magnetic roll and a tensioning idle roll driven by a motor. A feeder discharges material on the belt on continues controlled rate of flow at uniform layer thickness. The ferromagnetic and paramagnetic particles adhere to the belt while the non-magnetic particles flow freely off the end of the conveyor. The division of paramagnetic and non-magnetic adjusted by using a splitter plate located below the belt. It can be configured stacked in any number of passes to suit the user requirement.

The open design of the G.A.S allows both coarse and very weakly magnetic materials to be treated successfully. Proven dry process application includes material from 75 microns up to 100 mm (4 inch) particle size, at through outputs from 200 kgs to 60 TPH

Our wide array of manufactured magnetic equipments comprises of suspended magnets and over band magnetic separators. For automatic and continuous separation of tramp iron from the product, our powerful over band self cleaning electro-magnetic separators are used to remove the tramp iron flowing along with the product on a belt conveyor. Our high precision over band magnetic separator is used for mounting over the conveyor across belts. The magnet unit is finished from electrolytic grade aluminium. The electro magnetic coils are made from high temperature resistant insulated aluminium conductor for continuous operation. There would be a short center belt conveyor fitted around the magnet unit mounted on to a fabricated framework. The conveyor is of highest quality rubber and canvas type bolted in position across the belt. The conveyor belt is made endless by means of belt fastener. The idler and drive drums are rolled steel constructions fitted with high tensile steel shafts and mounted in self-lubricated, dust sealed plumber blocks. Adjuster screws would be fitted to provide tensioning take up on idler drums.

Suspended permanent magnets are developed for high separation performance in over the belt conveyor applications. These heavy duty permanent magnets are used in welded construction and are effective in removal of tramp metal in high volume applications.

The electro magnets are fabricated for high volume applications. The biggest advantage of this is the “deep reach” and to be turned on and off ability. Built over a vibratory bed or belt conveyor, these magnets have strength, robust and long lasting.

We are engaged in manufacturing and supplying a wide series of magnetic separator pulleys used as head pulleys in belt continuous and automatic removal of tramp metal from material flow.

Known for robustness and durability, the comprehensive range of powerful permanent magnet separation pulleys manufactured by us meet the size and installation requirements of most conveyor systems applications. At G.A.S the magnetic pulleys are manufactured in four different hub styles-extended hubs, flush hubs, recessed hubs and with out hubs. Our manufactured magnetic pulleys are available with or without lagging and with crowned or flat faces.

The pulley shafts are removable mild steel and are available with optional stainless steel shaft. The standard size of the pulley varies from 4” diameter by 10’’ face width.

Magnetic sweeper is an engineering product meant for clearing floors from numerous small ferrous metal objects such as nails, tacks, nuts and bolts. It is well built and incredibly strong with powerful magnetism. The magnetic sweeper is available both in light and heavy weight. It is housed in stainless steel structure and is fitted with two large robust rubber wheels with puncture-proof tyres. The steel handle is controlled by a long tubular steel handle, which can be dismantled.

The magnetic sweeper has following features:

The liquid line separators developed by us are designed for heavy-duty large volume liquid and semi-liquid line flow system. This employs a slip in cage of stainless steel permanent magnet tubes, which is used to capture tramp metal particles, migrate to the rear of tubes, where they remain safe from wash off unless these are not cleaned. These tubes are hanged on top access bolt on steel plate and seal, which is easy to clean. The magnet cage is lifted out after the top is removed for cleaning and than it is reinstalled.

Plate magnets are important industrial separators that are meant for the separation of fine ferrous materials and large pieces of tramp iron, from many types of free flowing and pneumatically conveyed material such as corn, sugar, flour, gravel & plastic etc.

The plate magnets also goes very well with powdery, moist, lumpy, and abrasive products and large debris that might choke, bridge, or cause rapid wear in cartridge-based separators. Plate magnets are flexible enough to be deployed above conveyors or below conveyor drive pulleys to capture contaminants.

Hump magnet separators are used to remove ferrous contaminants iron nuts, bolts, wire etc. from the conveyed material. With the hinged doors, cleaning the magnetic surface is quick and easy. The unit can be mounted directly in the air stream with the square to round transitions, which can be provided.

Hump magnetic separators consists of two plate magnets, which are hinged and gasketed to the rugged steel housing. These plate magnets can be unlatched and swing open for quick manual cleaning.

Bullet magnet is aerodynamically shaped with solid stainless steel nose cone and flow through design of the bullet magnet allows it to be used anywhere in pneumatic line system. The bullet magnet we offer can be used for processing equipment and bulk load out to assure product purity and protect machinery from tramp metal damage. The nose cone (code) diverter and magnet assemble bullet, designed to maintain balanced flow through the housing thereby maintaining uniform velocity in line flow ideal for dilute phase system, typical bullet magnet application includes processing of powder and granular, flour, chemical, plastic food stuff, pharmaceutical and mineral material. It has following features.

Magnetic filters are made up of stainless steel tubes. Each tube consists of an aray of permanent magnetic discs specially designed and configured to generate high magnetic forces. The filters can be supplied using either ferrite or rare earth magnets. The tubes have a diameter of either 1” or 1.5”. The filters can be supplied in various size with width and length varying from 9 to 24 inches. Circular or rectangular shapes are offered. Customized sizes and shapes also be offerered.

Magnetic filters are used for trapping ferrous impurities in various minerals, plastics foods stuffs, raw materials, etc. in powder form. They can be installed, in hoppers, chutes etc.

Multiple stage filters (housing) are useful for high purity applications In a housing, more than one filter is placed one over the other. This is to ensure that if the ferrous impurity is not trapped in the first stage, it will be trapped in the subsequent stages There are two types of housing manual cleaning type and Self Cleaning type.

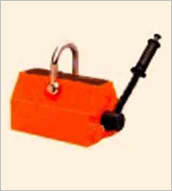

The permanent lifting magnets, delivered by us are ideal for handling steel plate, forgings, die-casting and similar items in machine shops.

In handling thick, non-flexing ferrous items our lifting magnets eliminate the need for slings, clamping devices or chains. With the help of our lifting magnets a person can perform operations individually, which saves time and labor. These are the best solution to simplify loading, unloading, handling steel items while receiving material in shipping areas & fast stacking, desk stacking, transfer of steel, plates, bars, angles and rounds.

We manufacture and supply screen separator, a unique particle size gradable separator designed for greater capacity per meter square of screening area & over size material discharge with relatively much less percentage fines than other screening machines.

The top weight on the motor shaft rotates in a plane close to the center of the mass of assembly. Rotation of the top eccentric weight creates vibration in the horizontal plane that causes material to move across the screen cloth to periphery. Increasing the top eccentric mass increases the horizontal throw, causing oversize material to discharge at a faster rate.

The bottom eccentric weight rotates below the center of mass, creating tilt on the screen, giving vibration in vertical & tangential planes. Increasing the vertical component of motion, which promotes turn over of material on the screen surface helping maximum quantity of under-size material to pass through the screen. The vertical motion minimizes blinding of screen by “near size” particles.

The tangential component of motion is controlled by the angle of lead given to bottom weights with relation to top weight. Variation in lead angle controlled the spiral pattern of material travel over the screen cloth can be set by the operator for maximum throughout & screening efficiency for any screen able product be it wet or dry, coarse or fine, heavy or light, hot or cold. Typical material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet.

Standard sizes are available in 24” 36” and 48” diametre custom sizes can also be made on request.

Vibrating screens are used for vibratory motors to drive the mechanism. It has several advantages like simplicity, compactness, and reduced maintenance and less installation cost. By mounting the entire drive mechanism on screen, many accessories are made by external drive motor, motor support, V belts and shaft drive components.

It is designed for wet and dry operation. These machines offer outstanding services in product sizing, regretting, medium recovery, and trash removal. Screen sizes range from 300 x 900 mm to 3000 x 9000 mm in single, double and triple deck configurations. The deck materials include wire mesh, polyurethane and perforated plate. Accessories such as dust enclosures, integral spray pipes, sub frames, outlet chutes are also provided. Rectangular screen separator made by us goes according to the pattern specification and requirement.

We manufacture a wide range of inclined screen that fulfills the specific requirement. These machines are powered by paired vibrating motors or three motors and tested externally by driven single oscillator mechanism. These screens can be made for variant configurations, number of decks and screen sizes.

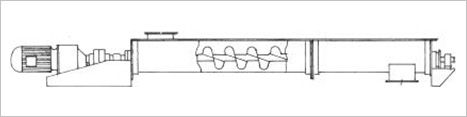

Electro magnet powered vibrator feeder developed by us contains high frequency reciprocating machine of light duty, capable enough for conveying bulk material from storage to processing or between processes at continuous controlled rate of flow.

Vibrating feeders are used in processing industries for handling any type of material like hot, damp, lumpy, dusty or abrasive for various functions like flow of material from storage, proportioning, blending, packaging, mixing, weighing, sprinkling and batching.

Vibrating feeders are available along with base mounted, over hanging or combined single magnetic drive or with twin or dual twin magnet drives or with multiple drives for serving as vibrating conveyors.

These feeders have tray mounted on the drive units that is located beneath the tray consisting of two sets, leaf springs connected to the mounting bracket, an electromagnet with armature and solid cast iron base. When magnetic coil of feeders is energized it gives horizontal vibrations to the tray, which ensures free, smooth, uniform, volumetric flow to the material that is fully variable from dribble to surge by externally step less with the help of a knob provided in the control panel.

The vibratory feeders we supply are available in variety of trough size and shapes as per IS: 8723 – 1978. These feeders are supplied through half wave rectifier resulting into 3000 vibrations per minute at 50 Hz. The amplitude of vibrations can vary to the feed rate externally with the help of variance provided in control panel. As there is no moving mechanical parts inside power unit such as gears, motors, eccentric weights, chains and bearing so it is absolutely maintenance free and no down time for process industries. The vibratory tray is heavily fabricated duly stiffened with angles. Wear resistance plate is also provided for varying abrasive materials in the tray that is made for individuals requirements. The best part is that it can be made dust tight. System is fitted with powerful electromagnetic coils, made from double fiberglass covered copper wire suitable for class H insulation for excellent result. The coil is molded in specially formulated resin to withstand any type of atmospheric condition.

We develop heavy duty vibro motor powered vibratory feeder that is a high frequency reciprocating machine of heavy duty, capable of conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow.

Vibrating feeders are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow of material from storage, proportioning and blending, packaging, mixing, weighting, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc.

We supply heavy-duty vibrating feeders with base mounted over hanging or combined single motor drive or with twin dual or dual twin motor drives or with multiple drives to serve as vibrating conveyors. These feeders are having a tray mounted on the drive units. This unit is located beneath the tray.

Vibro finishing machine is a bowl type centrifugal finishing machine. The machine bowl is loaded with suitable ceramic / plastic or steel media and the components to be processed. The mutual rubbing action takes place inside the chamber due to the gyratory vibrations, Compared to other simpler processes this method completes the deburring process faster.

Vibro finishing machine is driven by powerful vibratory motor causing intense rubbing and trouble free output.

The vibratory motors preffered by us are fully enclosed with 3-phase squirrel cage induction motor that has adjustable eccentric weight mounted on both the end of shaft. By adjusting both eccentric weights, we can easily vary the rate of vibration. The selection of shaft material and bearing should be carefully done to withstand heavy radial load.

It is mainly used in vibratory screen, feeder, silos, bin and other material handling equipments. We are engaged in developing foot mounted and flange-mounted types available in different capacity. Efficiency and low maintenance are the main feature of vibratory motor.

Bucket Elevator : Bucket Elevators Available in M.S/ S.S./P.V.C. Sizes Varies From.

Bucket Sizes : 100 × 50 × 70 125 × 60 × 75 200 × 75 × 100 Chain drives / Belt Drives both are available depending on Customer requirement.

Sizes varies from : 600mm, 750mm, 900mm & 1200mm width at on inclination of 17º & 20º. Flat Belt, Slat & Bag conveyors can be manufactured as per the customer requirment.

Sizes Varies from :

Note : Spares like rollers, bucket, belts, screws are available as per customer requirments.